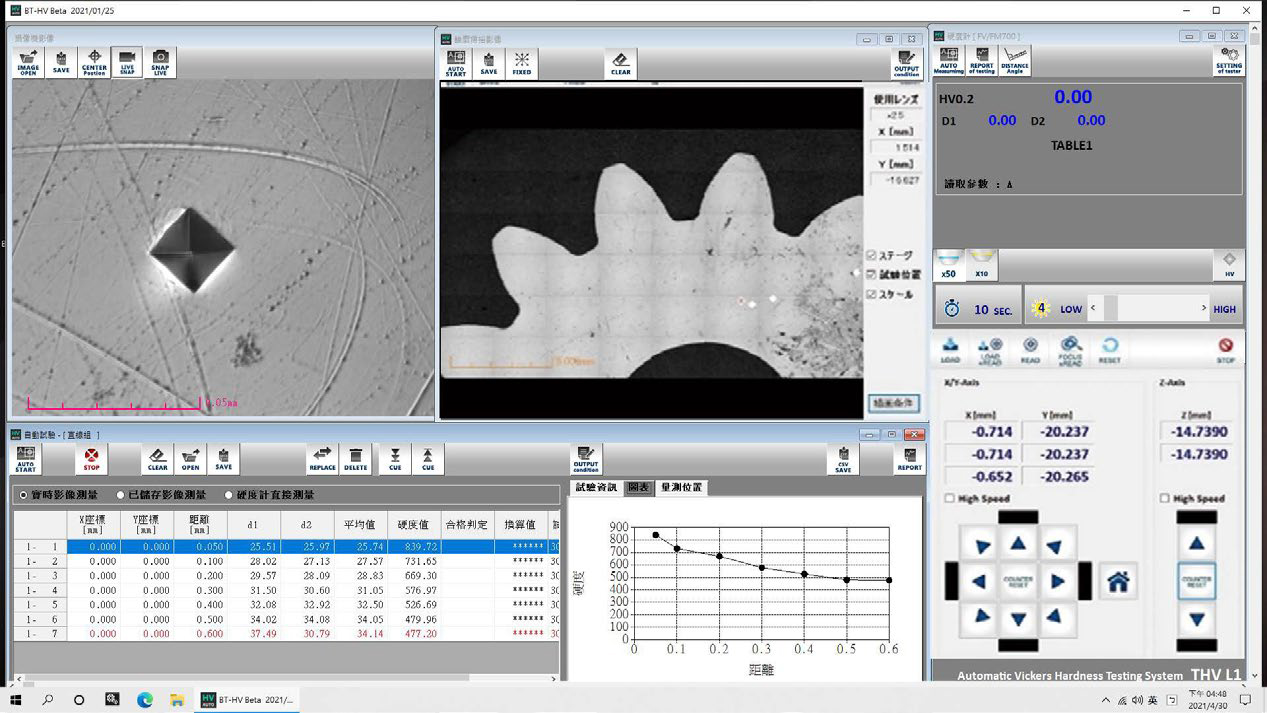

THV-SA combines a micro/Vickers hardness tester with this system, enabling automatic indentation measurement and platform control during multi-point measurement processes. This reduces measurement result variations caused by operator errors, shortens hardness testing time, and lessens operator fatigue, thus streamlining measurement work and saving significant labor.

**Equipped with an automatic X-Y positioning stage.

Utilizing sample shape recognition for quick program setup, complex multi-point testing tasks can be automated. Simply pre-set and select the desired path for automatic measurement and recording of a series of continuous test points.

Includes Various Measurement Modules Includes modules for case depth measurement, specialized decarburization testing for screws, and random point measurement, offering path setting options to meet the diverse needs of all users.

Efficient Stage Movement and Alignment Double-click to move the center and drag for precise stage movement. This streamlines sample setup by aligning the measurement origin through these movements.

**Image Processing Software

Advanced image processing software significantly improves the measurement of indentations on scratched and dirty sample surfaces.

**Indentation Image Storage

Images of measured indentations are saved. Data correction can be easily and quickly performed by re-measuring saved indentation images without the need to move the workpiece.

**Multiple Report Output Formats and Statistical Analysis Functions

In case depth measurement, the effective depth of hardness (Eht, Rht, Nht, etc.) specified in various ways is immediately displayed on a graph and recorded upon measurement completion.

The system offers various data processing, display, and output functions, such as multi-point measurement data, hardness distribution graphs, layer depth, maximum, minimum, average, range, standard deviation, pass/fail judgment, converted hardness, etc. It is equipped with color graphing capabilities and Excel data transfer functionality.

The system includes: